Stop Guessing: Why the P.A.T.T.I. Delivers True Coating Adhesion Values

In the competitive world of coating adhesion testing, where precision can make or break quality assurance, the P.A.T.T.I. (Pneumatic Adhesion Tensile Testing Instrument) stands unrivaled as the market leader. Invented and refined by SEMicro over decades, this portable powerhouse delivers unmatched accuracy, setting it apart from hydraulic or manual competitors like the PosiTest or Elcometer models.

What elevates the P.A.T.T.I. is its patented self-aligning piston design, which ensures uniaxial tensile loading perpendicular to the test surface. This eliminates operator bias inherent in hand-pumped devices, where misalignment skews results and compromises repeatability

Unlike competitors that rely on varying dolly sizes for load adjustment—often leading to inconsistent pulls—the P.A.T.T.I. swaps modular pistons for targeted ranges up to 10,000 PSI in its Quantum series, providing "true tensile testing" even on challenging substrates like concrete or curved surfaces.

Industry experts note its superior repeatability, often yielding the highest adhesion values, which is why paint manufacturers favor it for product data sheets.

Compliance with ASTM D-4541 standards as a Type IV instrument further cements its reliability for pull-off strength measurements on paints, polymers, inks, and thermal-sprayed metals.

Its pneumatic system, powered by CO2 cartridges or inert gas, enables field portability without bulky hydraulics, and it excels in extreme conditions from 32°F to 212°F

Lighter and more ergonomic than rivals, the P.A.T.T.I.-K model weighs less while testing up to 5,000 PSI, making it ideal for on-site inspections.

In an era of stringent corrosion protection and quality control, settling for less accurate tools risks costly failures. The P.A.T.T.I. isn't just a tester—it's the gold standard, empowering industries to ensure durable, high-performance coatings that withstand real-world demands.

"Looking to improve your Adhesion Testing results?"

Read the following White Paper to learn more about our newest Patent-Pending Product (still in development)

"The most accurate adhesion tester on the market!"

Looking for the Digital model? CLICK HERE.

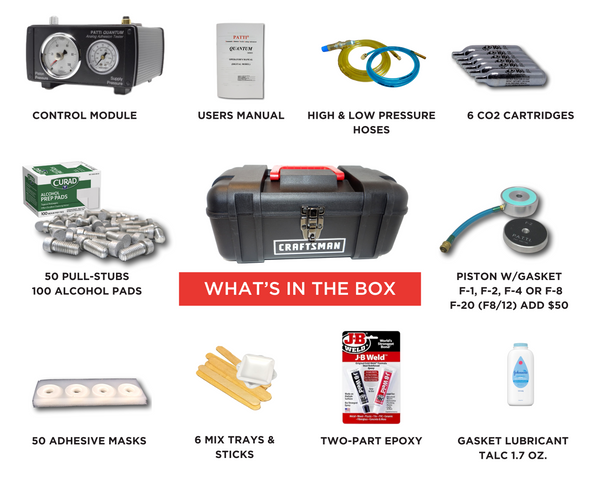

PATTI® QUANTUM FEATURES:

- The same quality you have come to expect from the PATTI®

- The powder-coated box is much more robust than previous PATTI®'s – will maintain its aesthetic value

- New regulator eliminates the internal pop valve, allowing for use of entire air cartridge

- New air cartridge capacity is twice that of other PATTI® models

- Simplified design requires fewer internal parts and reduces the frequency of maintenance/repair

- With the exception of the new, higher capacity CO2 Cartridge, you can use the same pistons, pull-stubs, and supplies as previous PATTI®'s

- The reduced number of internal parts makes the PATTI® QUANTUM lighter than other PATTI®'s and more portable than ever

PATTI® APPLICATIONS:

- The self-aligning PATTI® QUANTUM quantitatively measures the adhesion strength of numerous coatings, including paints, polymers, ceramics, inks, films, adhesives, and thermal or arc-sprayed metals.

- Laboratory or field use.

- The test surface can be smooth, rough, porous, flat or curved (please contact us for application-specific solutions). Custom-machined pull-stubs are available at any size, either flat or with a radius to match curved surfaces.

- The PATTI® can also be used to test the strength of adhesives under non-room environmental conditions from 32-212 degrees Fahrenheit (0-100 degrees Celsius).

EASY TO USE:

- The PATTI® Quantum uses compressed inert gas to apply a continuous tensile load to an aluminum pull-stub which is bonded to the test surface with an adhesive.

- After the adhesive has cured, the operator attaches the selected piston. Then the operator pushes and holds the "RUN" button. A continuous load is then applied perpendicular to the pull-stub until failure occurs, or until a specified load is reached.

- The PATTI® can be pressurized with CO2 cartridges to make it portable for field use. In the laboratory, nitrogen or any clean inert gas system providing at least 100 psig (up to 160 psig) can be used.

The PATTI® features a patented piston design which assures uniaxial

alignment with the pull-stub axis for "true tensile testing":

MEASURES ADHESION STRENGTH UP TO 10,000 PSI:

There is a different piston for each load range shown in the table below. At least 100 psig supply pressure (up to 160 psig) is required for all piston sizes and all pistons are self-aligning.

| Piston |

Load Range (PSI using 1/2" dia. pull-stubs) |

Piston Diameter | Price |

| F-1 | 50-500 | 1 3/4" (1.75") | $399.00 |

| F-2 | 100-1000 | 2 1/4" (2.25") | $399.00 |

| F-4 | 200-2000 | 2 7/8" (2.875") | $399.00 |

| F-8 | 400-4000 | 3 3/4" (3.75") | $399.00 |

|

F-8/12 (F-20) (3 Load Ranges) |

F-8; 400-4000 F-12; 600-6000 F-20; 1000-10,000 |

5 3/4" (5.75") | $449.00 |

MEETS SPECIFICATIONS:

The PATTI® instrument and method conforms to ASTM D-4541, "Pull-Off Strength of Coatings Using Portable Adhesion Testers".

Also can be used for the testing of coatings on concrete according to ACI 503-30 Appendix A, A.1. 50mm pull-stubs required.

SPECIFICATIONS:

- Gas Supply: self-contained or external supply, 100psig

- Weight: < 4 pounds

- Dimensions: 8" (20.3cm) x 3 1/8" (7.9cm) x 6" (15.3cm) (Control Module)

- Load Range: 1-10,000 psi using 1/2" pull-stubs

- Operating Temperature Range: 50-120 degrees Fahrenheit

- Certified calibration available at an additional fee

- Accessory for testing adhesives available

- All pistons are self-aligning